With component sizes shrinking and board complexity rising, maintaining a quality standard is challenging. Luckily, the systems responsible for identifying quality defects have also undergone technological advancements. As a contract manufacturer, we have to identify trends early and adopt the technologies that create value for us and ultimately, our customers. Here are some of our quality and testing processes that we implement that help deliver great results for customers.

Choosing between Surface Mount Technology and Thru-Hole

by VR Industries posted in Printed Circuit Board Assembly

Until 40 years ago, through-hole mounting was the dominant method for placing electronic components on printed circuit board assemblies. For years, this method was used to place virtually all components in the time period from the 1950’s until surface mount technology became popular in the 1980’s.

15 PCB Design for Manufacturing Considerations

by VR Industries posted in Printed Circuit Board Assembly

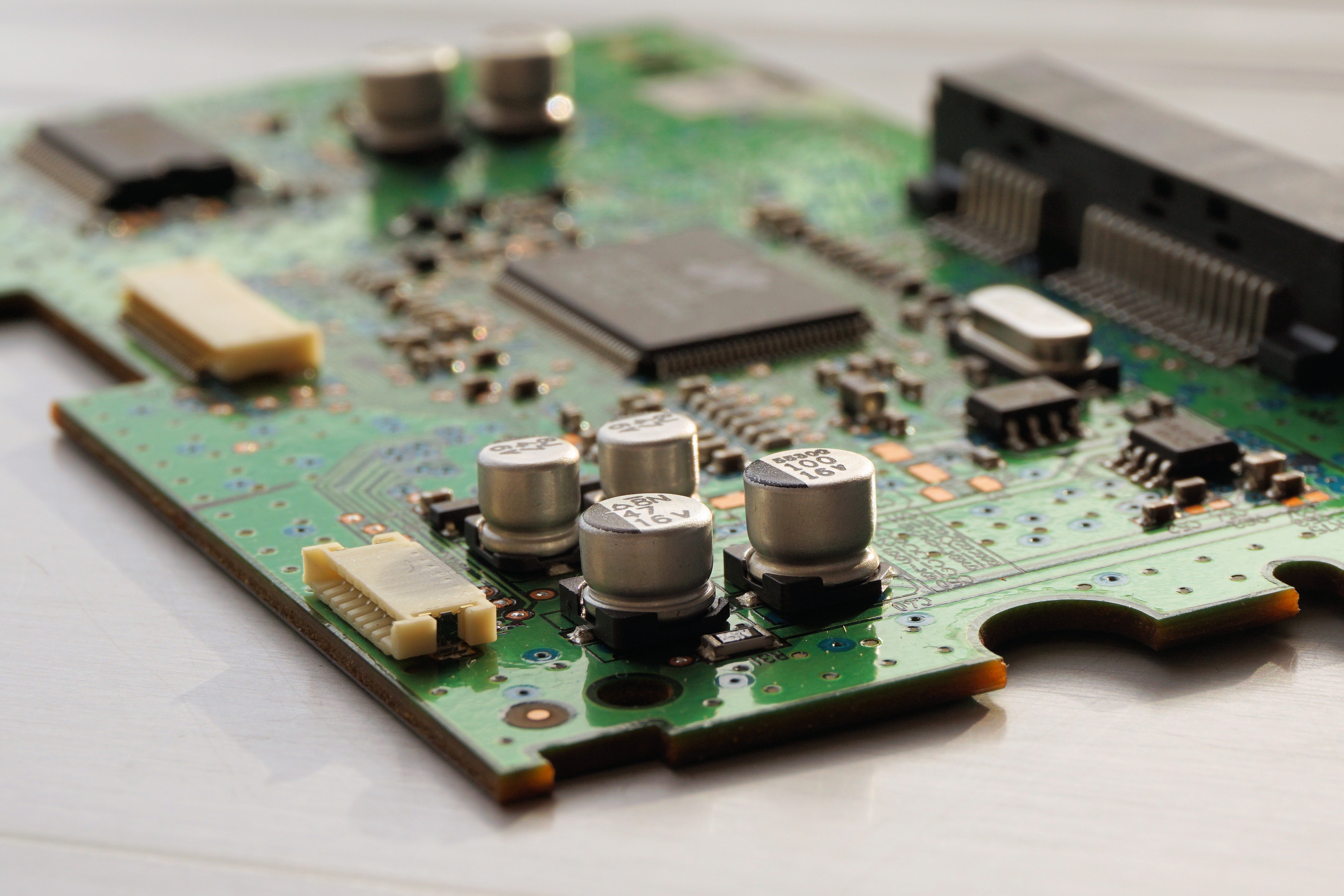

Engineers encounter innumerable variables when designing a printed circuit board, especially when you consider that even though a printed circuit board may function properly, it doesn’t necessarily mean that it can be manufactured in a way that maximizes quality and reduces cost. Completing a PCB design is a struggle between different constraints which encompass time, budget, and functionality, with manufacturability often seen as an afterthought. However, if engineers involved their manufacturing team and considered a comprehensive design for manufacturing review, many common problems could be avoided. In addition to increased manufacturability, engineers can benefit from reduced cost and time to market.

As a contract manufacturer, we repeatedly see the same mistakes regarding design for manufacturing. These hold back projects and create additional design costs and delay timelines. We’ve compiled a list of the top 15 “gotchas” for PCB design to make sure your board is set up for success when it’s time to transition to manufacturing. This is not a completely comprehensive list, but we always tell prospective customers that if these rules are followed, about 80% of DFM mistakes can be avoided.

This list is based from over thirty years of experience and it’s our hope that they can help you see success with your next project.

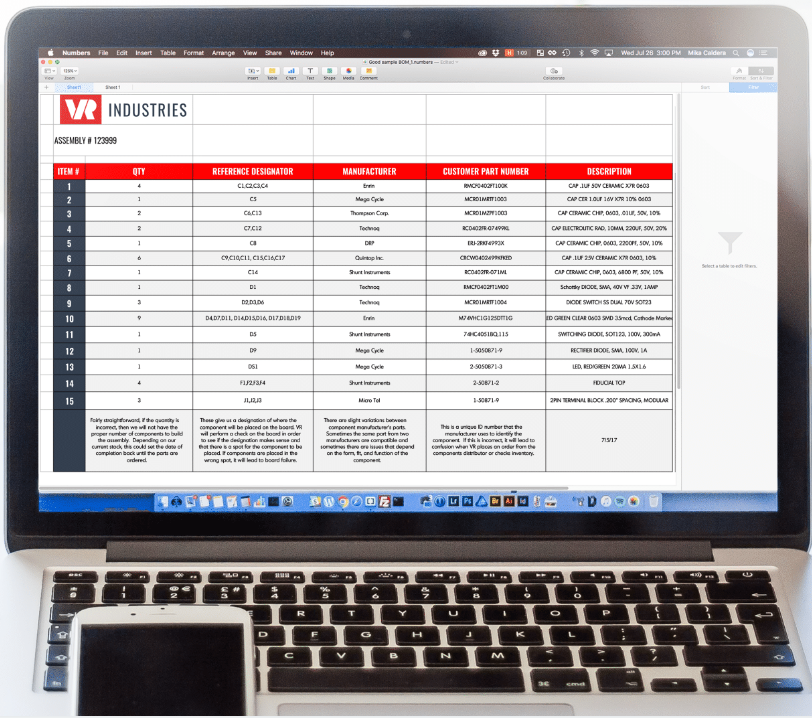

The decision to include electronics components and other items involved in electronics manufacturing in the list of products subjected to the new 25% tariff on Chinese imports has left manufacturers looking for ways to explain how these actions will both impact production and how customers can mitigate some of the effects.

With global supply chains becoming the norm over the past few decades, final product assemblies include labor and parts that oftentimes span the globe. While VR Industries labor is all performed at our facility in Warwick, RI, components and materials are sourced from several distributors - both domestic and international. As a result, decisions that impact our supply chain will ultimately affect our customers. This is being witnessed across US manufacturers in industries that deal with products impacted by the tariffs.For most individuals involved in outsourced contract manufacturing, Bill of Materials is a common term. For the few that aren’t familiar, the Bill of Materials (BOM for short) is a spreadsheet document that lists out all parts needed to complete a build and it is a major aspect of the supporting documentation needed to deliver an RFQ/RFP.

On-Shoring: The VR Model

by VR Industries posted in News

The U.S. manufacturing index hit its highest mark in almost three years this past June, driven by increased production demand. As contract manufacturers continue to see an increase in orders, OEM’s are experiencing the benefits of working with a domestic manufacturing partner.

We’ve helped some of our customers readjust to domestic production and transition back to working with a local partner. We call this our “On-Shoring” model.

While there are numerous benefits to On-Shoring, here are a few of most prominent ones:

How Design Can Affect Quality

by VR Industries posted in News

Design for Manufacturing is a critical step in any PCBA or Electromechanical project. Outcomes vary depending on the complexity of the build but often times our customers experience increases in quality yields and component cost savings. To understand how customers, realize these benefits it’s important to understand what DFM is and how we conduct it here at VR Industries.

3 Vital Inspections We Perform That You Might Not Be Aware Of

by Steve posted in Electromechanical Assembly / Box Build, Markets, News, Printed Circuit Board Assembly, Program Management

With component sizes shrinking and board complexity rising, maintaining a quality standard is challenging. Luckily, the systems responsible for identifying quality defects have also undergone technological advancements. As a contract manufacturer, we have to identify trends early and adopt the technologies that create value for us and ultimately our customers. Here are three quality processes we offer that help deliver great products to you.

Can PCBA Accelerate IoT Adoption in the Healthcare Sector?

by VR Industries posted in Medical, News, Printed Circuit Board Assembly

It is only a matter of years before flexible health care technology saturates modern medicine. As paper record keeping gives way to electronic information management systems built on a network of connected assets, patients stand to gain truly "round-the-clock" care from their medical providers in the form of wearable sensors made from rigid-flex and flexible printed circuit boards.