Behind every device is a manufacturing team who created it. This statement rings even more true for printed circuit boards, even though consumers may not recognize it.

The growth of technology is spurring a need for highly technical electromechanical assembly within the industry. The only issue is, there aren't enough qualified applicants to meet the demand.

Supply lower than demand

The current candidate-driven job market is hitting the manufacturing sector especially hard as the industry is becoming highly technical. According to a survey from the Society for Human Resource Management, 68 percent of recruiters found it difficult to hire full-time staff in the market in 2016. This is up 18 percent from 2015.

This hiring deficit stems from a number of factors, SHRM reported:

- Reduction in applicants with work experience

- Highly-competitive hiring

- Shortage of candidates in local areas

All of this is coming at what is potentially the best time in America for the manufacturing sector. After the recession hit in 2008, the unemployment rate jumped from 5.1 percent in January to 13 percent in January, 2010, according to the Bureau of Labor Statistics. Since then, though, the unemployment rate was last clocked in at a healthy 4.7 percent for May, 2016. With software, hardware, Internet of Things and other interconnected technologies taking off in the digital era, the need for employees has never been higher. Unfortunately, there just aren't enough qualified applicants.

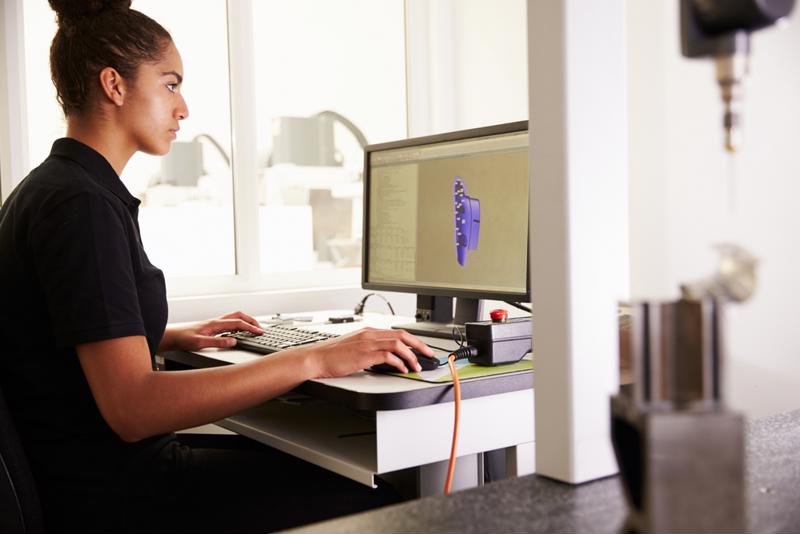

PCB assembly companies with lean manufacturing methods will benefit as technology becomes more technical to create.

PCB assembly companies with lean manufacturing methods will benefit as technology becomes more technical to create.

The golden age for manufacturing

All of this comes in light of the fact that Marc Andreesen's prediction that "software is eating the world," is coming true, according to Industry Week. For some industries this is forecasting the end as we know it. In manufacturing, though, it's creating opportunity after opportunity.

Every automated task has a PCB behind it, relaying information and allowing it to perform. With the amount of devices flooding the market now, Industry Week believes the assembly sector is set up to prosper. PCB manufacturing companies with flexible manufacturing methods will ultimately control a large portion of the new market as companies search for factories that can come up with new designs and approaches to fitting smaller PCBs into tighter spaces.

Products like wearables require a different type of technology than 3-D printers or virtual reality gear. Companies with lean manufacturing methods often have the agility to respond to changes in trends that necessitate a switch in design to achieve ultimate desired functionality. As these connected devices become smaller, these PCB assembly teams will become even more valuable because of the consistent lack of qualified candidates on the market.

The quick progression that automation has seen in terms of taking over industries has been a boon for the manufacturing sector, and its benefits will only continue to grow. Factories must be able to fill staffing needs with qualified candidates in order to truly take advantage. Companies that incorporate lean manufacturing methods into their PCB assembly will surely gain a larger share of the available market as new technology will require constant deviation from the norm.