Whether your company is a startup with a great idea for a product or your business has been offering a variety of consumer goods for years, you must conduct your due diligence before choosing a manufacturing partner. After all, the quality of your items and the reputation of your brand is on the line if your manufacturer doesn't consistently perform, and that's not even to mention the financial challenges associated with manufacturer mistakes. As such, you must be prepared to learn everything you can about potential manufacturer partners before signing on that dotted line.

Here are five things you should know before choosing your manufacturer.

1. Your business needs

You've got the product spec'd out, and you've done your homework on materials sourcing and manufacturing costs. You know generally what type of manufacturer you should look for, but when it comes to specifics with respect to your business, you might have no idea where to start.

"Create a list of corporate requirements."

Business Bee contributor Lisa Poulsen recommended creating a list of corporate requirements. These have more do with meeting needs, than manufacturing processes themselves, and that's why they are so important. Poulsen listed a few criteria that you should consider and remember when trying to pick a manufacturer:

- In what quantity do you want to order?

- What are your preferred delivery lead times?

- How would you like to receive your manufactured goods?

- What type of return policy is acceptable?

- What are the payment terms and conditions?

2. Current customers

After creating your list of manufacturer standards, you should start searching for information on the current customers of some companies. Doreen Bloch told Business Collective why this is important. For one, she explained that you need assurance that the manufacturer you choose can perform, and clients will be honest. Secondly, Bloch said that if you look into manufacturers' customer lists, you could find a competitor there, and in that regard, you can pick a better one.

Furthermore, with insight into manufacturers' clients, you can gauge the quality of service, as Matt Hunckler of Verge noted, according to Business Collective. He asserted that you want to know how much your partner is producing and whether you're on the higher or lower side of that equation.

3. Quality assurance standards

The quality of manufactured goods determines your success. Therefore, you should follow Entrepreneur contributor Shane Broesky's advice and ask potential manufacturing partners what their quality assurance processes are like. Are they conducted prior to large productions? As a note, Broeksy said this is particularly important when electronics are involved.

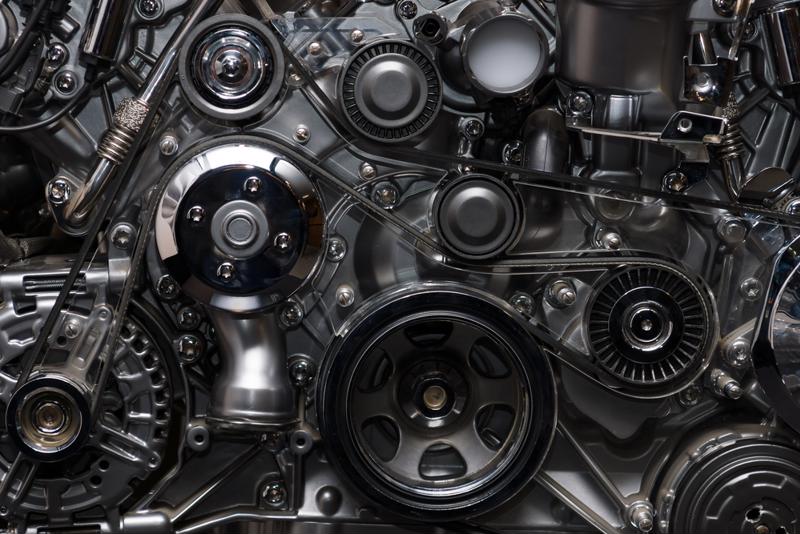

A manufacturer is the engine that runs your production, making this choice very important.

A manufacturer is the engine that runs your production, making this choice very important.

4. Size and capacity

Manufacturers come in all sizes, and by identifying the production capacity and employment numbers of a company, you can prevent a lot of heartbreak. Broeksy wrote that you should determine how large their operations are and how long they've been around. In that regard, choose one that meets your business needs - if you have lesser production demands, there is nothing wrong with choosing a smaller manufacturer.

That said, Broesky said that you need to think long term. For example, if you forecast rapid growth over the next six months, you obviously should opt for a manufacturer with a larger production capacity to prevent problems at scale.

5. Whether it'll be an actual partnership

You're looking for a manufacturer, but what you're really vetting is how well you can partner with that company. Lane Campbell of June told Business Collective that you should determine what the manufacturer will gain from working with your company, and therefore, you should discuss mutual benefits. Meanwhile, Kim Kaupe of ZinePak suggested inquiring if you'll help each other expand their operations.

You're probably saying, "But what about outsourcing versus domestic manufacturing? That's a huge factor in choosing a manufacturer." In that case, check out our other blog post on the pros of in-sourcing. For a complimentary partnership assessment with VR Industries fill out our form here.